High Precision Customized Brass CNC Machininig Parts Motor Shaft Sleeve Coupler for Auto Parts

- Price

- US $3-5

- Model

- OEM

- MOQ

- 1 piece

Item specifics

- Material

- steel,brass,aluminum,stainless steel

- Process

- CNC machining,Turning,Milling,Hot forging,Cold heading

- Requirements

- No burr,Scratches,Dents,Pits,Oil stain

- Package

- Bulk packing , Cartons, Pallets, Wooden case

- MOQ

- 50 pcs

- FOB Port

- Qingdao

- Lead time

- 15-20 days.

- Shipping

- by sea, by air, by DHL, UPS, Fedex , TNT & etc.

- Main Export Markets

- USA, Canada ,Britain , Belgium , Germany, Mexico, Netherlands, Japan , The United Arab Emirates

- Payment method

- T/T, PayPal , Western Union

Review

Description

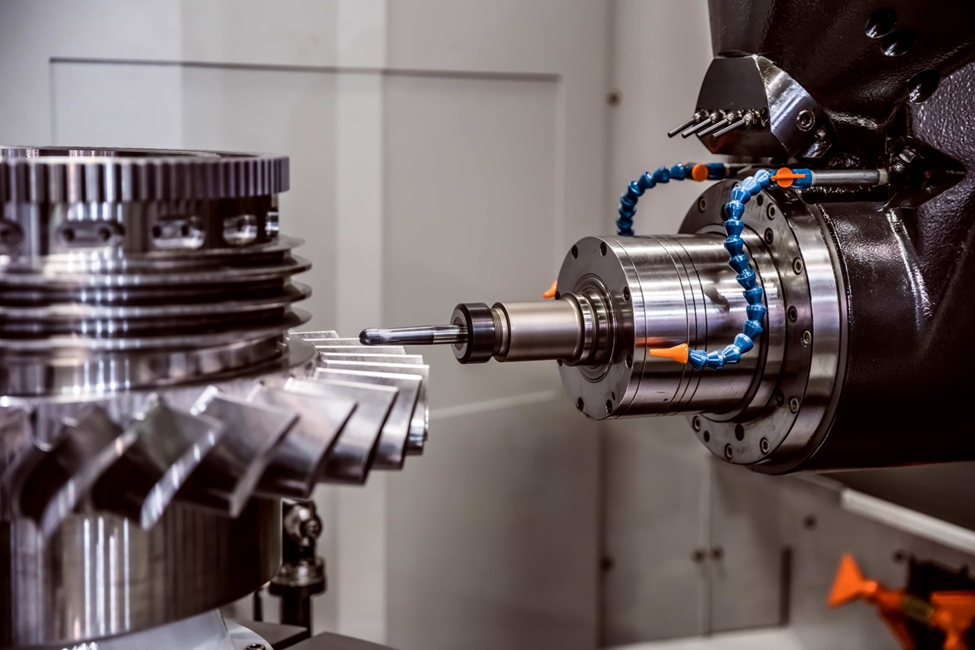

High Precision Customized Brass CNC Machininig Parts Motor Shaft Sleeve Coupler for Auto Parts

|

Product Name

|

High Precision Customized Brass CNC Machininig Parts Motor Shaft Sleeve Coupler for Auto Parts |

||

|

Quality Assurance

|

We promise 100% inspection before shipping

|

||

|

Material

|

Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc.

|

||

|

Brass Alloy:3600/ 3602 / 2604 / H59 / H62 / etc.

|

|||

Stainless Steel Alloy:303 / 304 / 316 / 412 / etc. | |||

Steel Alloy:Carbon Steel / Die Steel / etc. | |||

Other Special Materials:Lucite / Nylon / Bakelite / etc. | |||

We handle many other type of materials. Please contact us if your required material is not listed above. | |||

Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting and so on. | ||

Inspection Tools | Projector etc. | ||

File Format | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. | ||

Machining Equipments | Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe /etc. | ||

What are the shaft sleeves used for?

The primary function of the shaft sleeve is to protect the shaft from packing wear at the stuffing box. Shaft sleeves also help to protect the surface of the shaft seal or the surfaces in contact from damage or abrasive wear.

In general, shaft sleeves are commonly found in single stage pumps. The pump shaft usually offers protection for pump from corrosion and erosion.