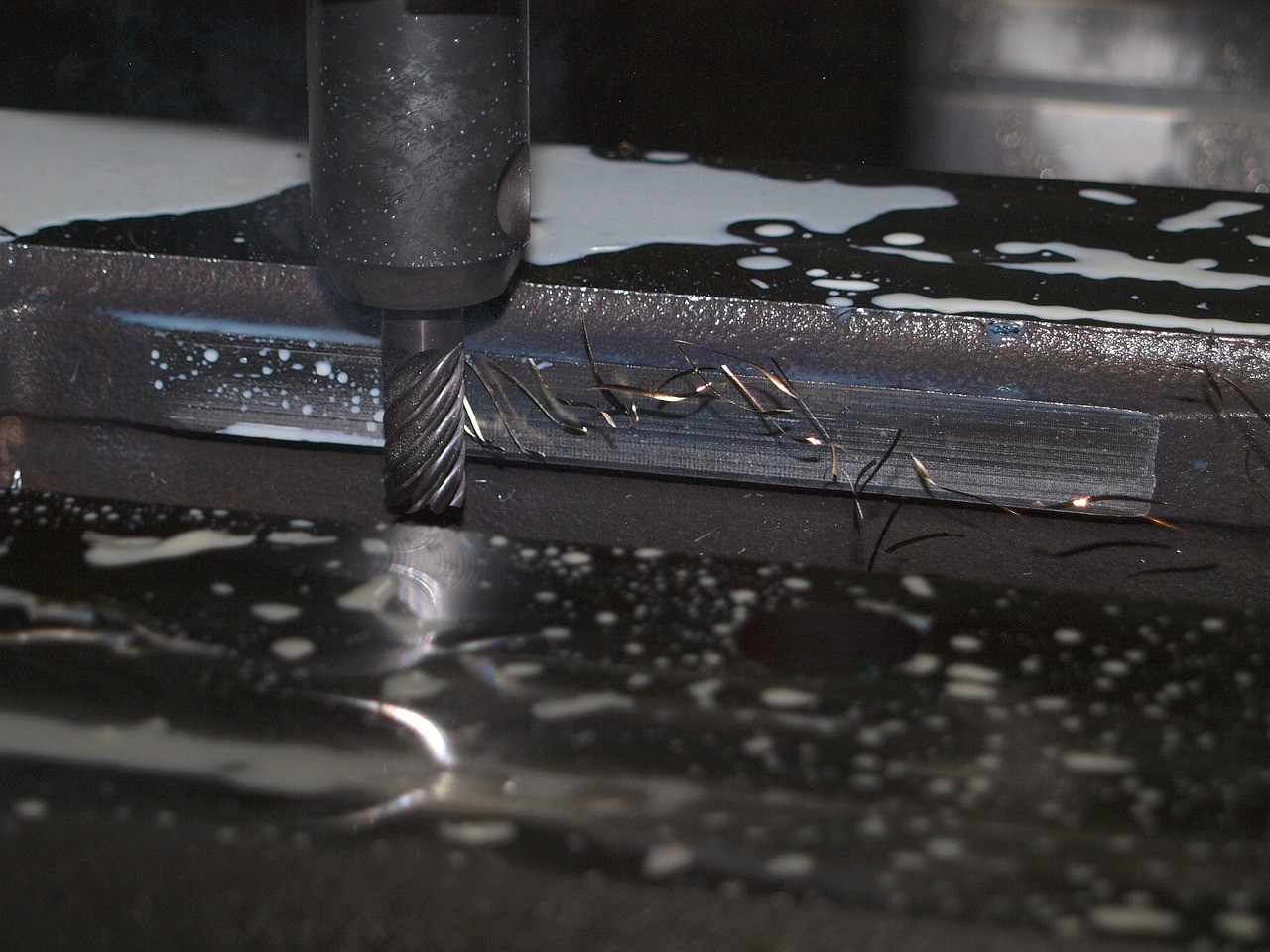

Customized CNC Milling Carbon Steel Frame Part for Tattoo Machine

- Price

- US $3-5

- Model

- OEM

- MOQ

- 1 piece

Item specifics

- Material

- steel,brass,aluminum,stainless steel

- Process

- CNC machining,Turning,Milling,Hot forging,Cold heading

- Requirements

- No burr,Scratches,Dents,Pits,Oil stain

- Package

- Bulk packing , Cartons, Pallets, Wooden case

- MOQ

- 50 pcs

- FOB Port

- Qingdao

- Lead time

- 15-20 days.

- Shipping

- by sea, by air, by DHL, UPS, Fedex , TNT & etc.

- Main Export Markets

- USA, Canada ,Britain , Belgium , Germany, Mexico, Netherlands, Japan , The United Arab Emirates

- Payment method

- T/T, PayPal , Western Union

Review

Description

Customized CNC Milling Carbon Steel Frame Part for Tattoo Machine

|

Product Name

|

Customized CNC Milling Carbon Steel Frame Part for Tattoo Machine |

||

|

Quality Assurance

|

We promise 100% inspection before shipping

|

||

|

Material

|

Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc.

|

||

|

Brass Alloy:3600/ 3602 / 2604 / H59 / H62 / etc.

|

|||

Stainless Steel Alloy:303 / 304 / 316 / 412 / etc. | |||

Steel Alloy:Carbon Steel / Die Steel / etc. | |||

Other Special Materials:Lucite / Nylon / Bakelite / etc. | |||

We handle many other type of materials. Please contact us if your required material is not listed above. | |||

Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting and so on. | ||

Inspection Tools | Projector etc. | ||

File Format | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. | ||

Machining Equipments | Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe /etc. | ||

The Advantage of the CNC Milling

1.High precision machining quality.

2.Multi-coordinate linkage can be processed to machining complex shapes.

3.When to change the machining part, operator generally only need to change the CNC program which can save production preparation time.

4.High degree of automation to reduce labor intensity.

5.Full-featured, available for wide materials.

2.Multi-coordinate linkage can be processed to machining complex shapes.

3.When to change the machining part, operator generally only need to change the CNC program which can save production preparation time.

4.High degree of automation to reduce labor intensity.

5.Full-featured, available for wide materials.