High Quality Custom-Made CNC Milling Open End Spinning Rotor for Textile Machinery

- Price

- US $3-5

- Model

- OEM

- MOQ

- 1 piece

Item specifics

- Material

- steel,brass,aluminum,stainless steel

- Process

- CNC machining,Turning,Milling,Hot forging,Cold heading

- Requirements

- No burr,Scratches,Dents,Pits,Oil stain

- Package

- Bulk packing , Cartons, Pallets, Wooden case

- MOQ

- 50 pcs

- FOB Port

- Qingdao

- Lead time

- 15-20 days.

- Shipping

- by sea, by air, by DHL, UPS, Fedex , TNT & etc.

- Main Export Markets

- USA, Canada ,Britain , Belgium , Germany, Mexico, Netherlands, Japan , The United Arab Emirates

- Payment method

- T/T, PayPal , Western Union

Review

Description

High Quality Custom-Made CNC Milling Open End Spinning Rotor for Textile Machinery

|

Product Name

|

High Quality Custom-Made CNC Milling Open End Spinning Rotor for Textile Machinery |

||

|

Quality Assurance

|

We promise 100% inspection before shipping

|

||

|

Material

|

Aluminum Alloy:5052 /6061/ 6063 / 2017 / 7075 / etc.

|

||

|

Brass Alloy:3600/ 3602 / 2604 / H59 / H62 / etc.

|

|||

Stainless Steel Alloy:303 / 304 / 316 / 412 / etc. | |||

Steel Alloy:Carbon Steel / Die Steel / etc. | |||

Other Special Materials:Lucite / Nylon / Bakelite / etc. | |||

We handle many other type of materials. Please contact us if your required material is not listed above. | |||

Surface Treatment | Blacking,polishing,anodize,chrome plating,zinc plating,nickel plating,tinting and so on. | ||

Inspection Tools | Projector etc. | ||

File Format | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. | ||

Machining Equipments | Machining Center / CNC Lathes / Grinding Machines / Milling Machines / Lathes / Stamping Machines/ Full Automatic Lathe /etc. | ||

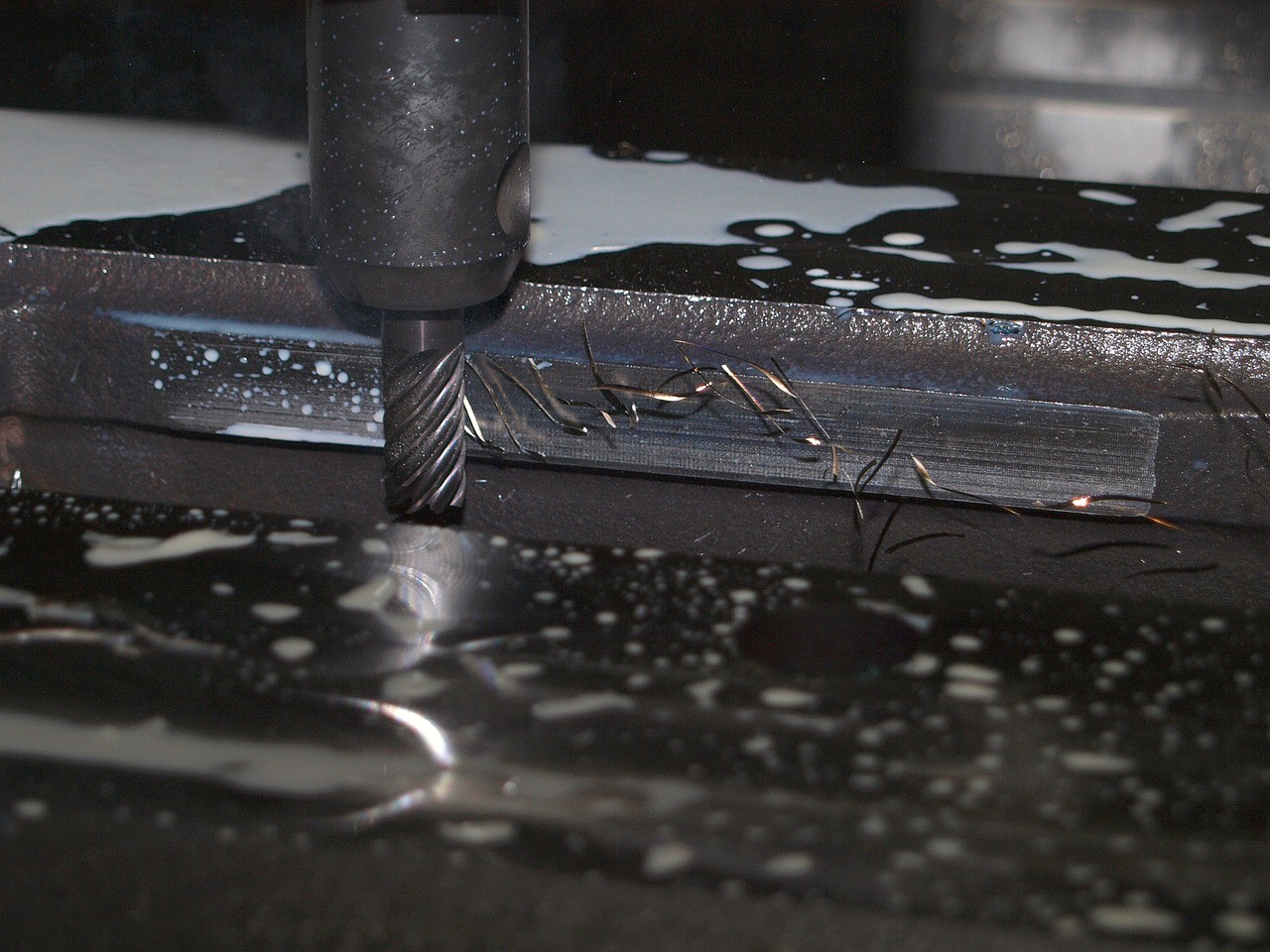

What is CNC Milling?

Milling is a cutting process that uses a milling cutter to remove the surface of the material by advancing in a direction at an angle. CNC milling machines are controlled in one of two ways: by computer or via manual override. Computer programming allows the machine to make the precise cuts required but the manual override allows a CNC machine operator to slow down or speed up or tweak the process if necessary.